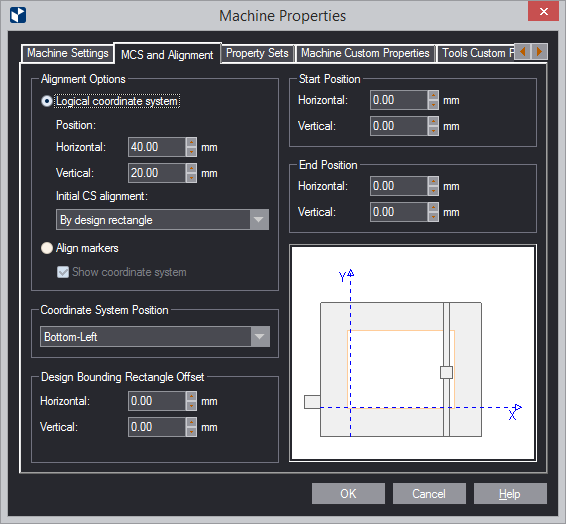

| Alignment Options |

Options for visualizing the current coordinate system.

These options do not position the coordinate system. |

| Logical Coordinate System |

Select this option if the machine has a logical coordinate

system. |

| Position |

Positions the coordinate system axes with respect to the

work area. |

| Horizontal |

Sets the horizontal offset of the design's bounding rectangle

with respect to the work area borders. Depending on the position

of the coordinate system, the offset may affect either coordinate

axis: the offset is set to lie horizontally with respect to

the nearest work area border, ignoring the position of the

coordinate system. |

| Vertical |

Sets the vertical offset of the design's bounding rectangle

with respect to the work area borders. Depending on the position

of the coordinate system, the offset may affect either coordinate

axis: the offset is set to lie vertically with respect to

the nearest work area border, ignoring the position of the

coordinate system. |

| |

| Align by design origin |

When the check box is selected, the origin of the machine's

coordinate system is aligned to that of the design. NOTE:

The CAM drawing must be refreshed for the changes to take

effect. IMPORTANT: Offsets set for the machine's coordinate

system in Horizontal and/or Vertical have preference. |

| Align Markers |

Select this option if the machine has align markers. |

| Show coordinate system |

Available when the machine has align markers. Visualizes

the coordinate system in the graphical area. |

| |

| Coordinate System Position |

The coordinate system's position over the machine's work

area. Four positions cover the possible cases. |

| Design Bounding Rectangle Offset |

Offset options for the visualization of the bounding rectangle

on the work area. |

| Horizontal |

Sets a horizontal offset with regard to the coordinate

axes. Depending on the coordinate system position, the offset

may derive from either axis, since it is set to always lie

horizontally. |

| Vertical |

Sets a vertical offset with regard to the coordinate axes.

Depending on the coordinate system position, the offset may

derive from either axis, since it is set to always lie vertically. |

| |

| Start & End Position |

Determines the position of the start and end points, displayed

on the screen as thick green  and blue

dots and blue

dots  ,

respectively. By default, the dots are positioned at the origin

of the coordinate system. ,

respectively. By default, the dots are positioned at the origin

of the coordinate system. |

| Start Position |

Horizontal, Vertical. Set the horizontal/vertical offset

of the start point in respect to the coordinate axes, thus

defining the start position of the generated tool path. Depending

on the coordinate system position, the offsets may originate

from either axis, as they are set to lay always in a horizontal,

respectively, vertical direction. |

| End Position |

Horizontal, Vertical. Set the horizontal/vertical offset

of the end point in respect to the coordinate axes, thus defining

end position of the generated tool path. Depending on the

coordinate system position, the offset may originate from

either axis, as they are set to always lay in a horizontal,

respectively, vertical direction. |

and blue

dots

and blue

dots  ,

respectively. By default, the dots are positioned at the origin

of the coordinate system.

,

respectively. By default, the dots are positioned at the origin

of the coordinate system.