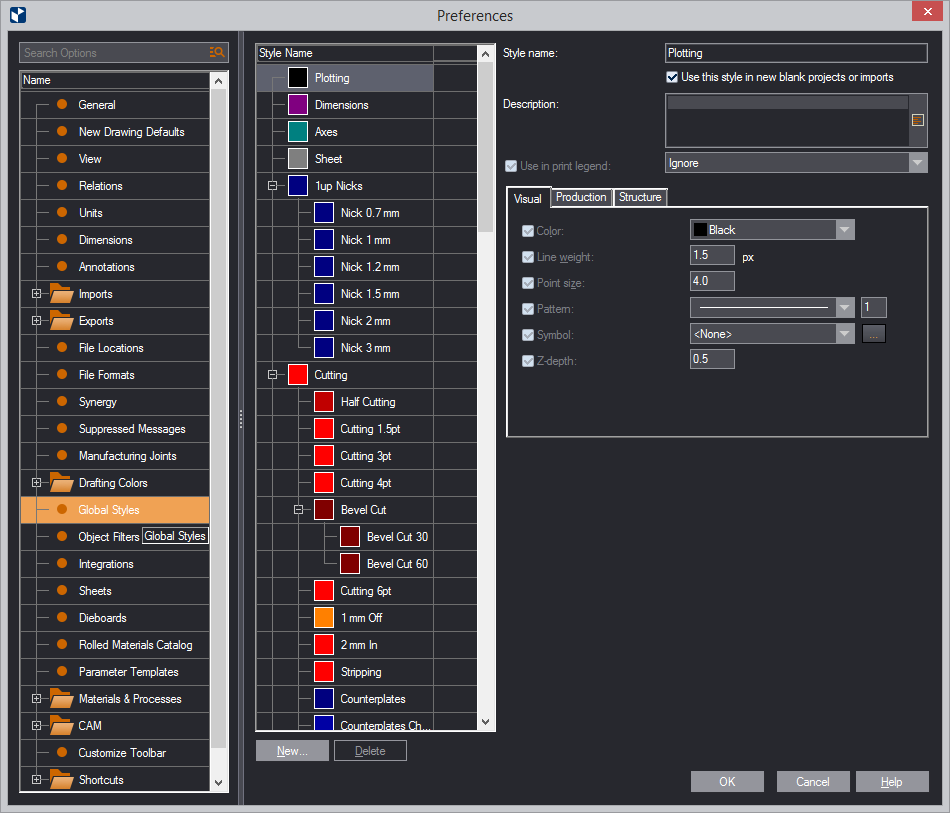

To define a global style

- Click New.

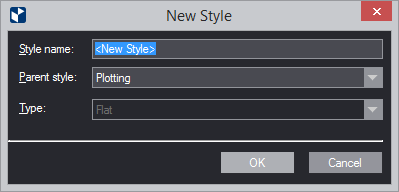

The New Style dialog box appears.

| Style name | Type a name for the new style. |

|---|---|

| Parent style | Select a parent style — that is, the style whose properties will serve as a basis for the new style. If you want the new style to have no parent (first-level style), select None. |

| Type | Available when None is selected in Parent

style. Can have one of the four style types:

|

- In the dialog, enter the values that you need, and then click OK.

- In the Global Styles dialog box, select the style you have just created.

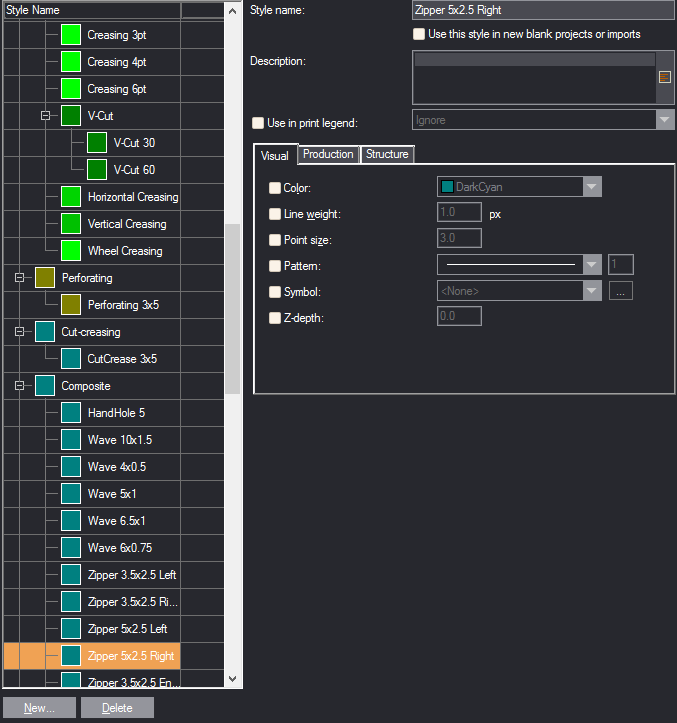

| Style name list | Lists all system and user-created global styles. Select the style you want to edit, and inspect its properties in the tabs on the right-hand side. |

|---|---|

| New | Opens a dialog box in which you begin to create a new global style. |

| Delete | Deletes the style selected in the list.

NOTE: You can delete only user-defined styles. |

| Style name | Sets the name of the style. Available only for user-created styles. |

| Use in new blank projects and imports | Makes

the style available in new blank projects or projects that

originate from imported files.

NOTE: Styles not set as default need to be added manually to projects. |

| Description | (Optional) Add notes about the style. |

| Use in print legend | Specifies how the lengths

of objects in this style will be listed in design frame legends.

The options are:

|

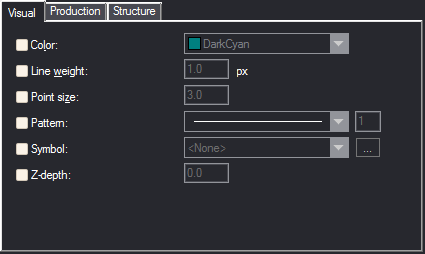

The Visual tab

In this tab, you set how the style will appear on the screen.

| Color | Sets the color for the style. The objects

to which this style is applied will appear in this color.

TIP: When you have modified the color of a parent style, to see its child styles in the same color, collapse and then expand either of the parent's adjacent styles. |

|---|---|

| Line weight | Sets how wide (in pixels) a line

or curve will appear. The value applies to objects in 1up,

layout, print, CAM and 3D drawings; it does not affect line

width in printing jobs and in the generation of tool path

for CAM jobs.

NOTE FOR COMPOSITE STYLES: EngView uses the line weight set here also for composite styles, if you have opted not to view the actual pattern of composite styles. |

| Point size | Points only. Sets how large points drawn in the selected style will appear. Value range: 0.10 – 15.00. |

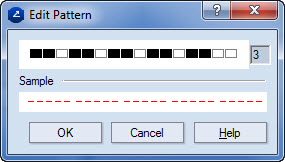

| Pattern | Sets the pattern in which objects

in the style will appear in 1up, layout, print, CAM and 3D

drawings. The dropdown list contains predefined patterns and

an option (Custom...) for creating custom patterns.

The second box sets the actual line width in points. Changes in this edit box are not visible on the screen; the value sets the line width of objects in the selected style in printing jobs and for the generation of tool path for CAM jobs (see the following note). NOTE FOR USE IN CAM: The value is important for toolpath generation: If the width of the respective CAM tool is narrower than the line width specified here, a different tool path may be generated, involving, for instance, the offsetting of wide lines for the cutting tool (for changes of the line width settings of a style associated with the cutting tool). CUSTOM PATTERN: You can create a custom pattern: Scroll to the bottom of the list, and then click Custom. Then, in the dialog box that appears, clear some black rectangles to create the pattern that you need, and then also set the line width.  |

| Symbol | Read-only. Symbol is the mark set to

indicate the style when listed in a legend.

NOTE ON APPLYING SYMBOL IMAGES: Optimal screen view of the style symbols is achieved when the height and width of images are 60 pixels x 60 pixels. This guarantees that printing the symbols at 300 dpi will produce a symbol size of 5 mm x 5 mm, ensuring distinct and clear appearance. The style symbol is always visible — if, for constructional purposes, a section of an object is hidden from view, the symbol reappears on the visible sections of the object. NOTES ON VIEWING SYMBOLS: To view style symbols properly:

|

| Z-depth | Sets the stack order of a style.

If multiple objects in different styles overlap, the object

in the style with the greatest stack order is visible on the

screen. The others are not visible regardless of when each

object was drawn. Value range: –1.00 to 1.00.

EXAMPLE STYLES: If the Cutting style has a stack order of 0.5 and the Axis style has a stack order of –0.4, when objects in the two styles overlap, the one in the Cutting style will always be visible and the one in the Axis style will never be visible. EXAMPLE SELECTIONS: The functionality applies also to selections. For overlapping objects, the object in a style with a greater stack order is always visible even if the object in a style with a lower stack order is selected. If objects in styles with the same stack order overlap, you see the one that is selected. |

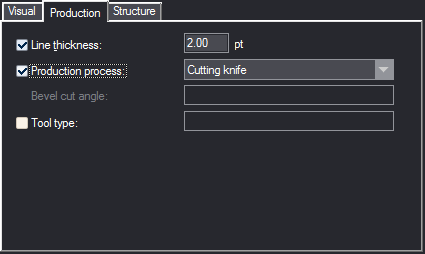

The Production tab

In this tab, you set the actual, physical properties of objects in the style as they should be processed in production.

| Line thickness | Sets, in points, the physical thickness

of objects in this style.

NOTE FOR COMPOSITE STYLES: The line thickness set here applies to printing or exporting jobs if you have opted not to view the actual pattern of composite styles. |

|---|---|

| Production process | Defines the technology that will be used for processing objects in the style. See a list of the available production processes. |

| Bevel cut angle | Available when the Bevel Cut process is selected in Production process. Sets the angle at which bevel cut will process the media. |

| Tool type | Used for integration with external

systems whose production processes may require additional

information (tool type) to distinguish between different tools

for production. (The Creasing Wheel process is an example.)

You can thus use the Tool Type property to define two styles

with different production processes. When such a process is

selected in Production process, the field becomes available,

and you can set a number in it.

EXAMPLE: You can define two Wheel Creasing styles (Wheel Creasing 1 and Wheel Creasing 2) that will serve two creasing wheel production processes. Wheel Creasing 1 will have production process Creasing Wheel (tool type 1), Wheel Creasing 2 will have production process Creasing Wheel (tool type 2). The Tool Type property plays no role in processes not related to production: Auxiliary, Panel Separator, Glue Area Contour, and Closed Area Contour. |

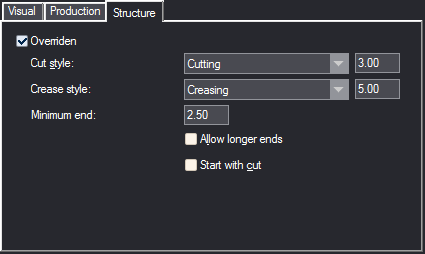

The Structure tab: CutCrease styles

| Overridden | Select the check box to set a style structure different from that of the parent one. |

|---|---|

| Cut style | In the dropdown list, sets the style of the cut and, in the value box, the segment length. |

| Crease style | In the dropdown list, sets the segment length. By default, the objects in this style start with sections in the style set in Crease style. |

| Minimum end | Sets the shortest length that endmost segment can have. |

| Allow longer ends | Corrects incomplete endmost segments that result after the pattern has been calculated. Learn more about how to use the longer-ends correction. |

| Start with cut | Select the check box to set that objects begin and end with sections in the style set in Cut style. By default, the objects in this style start with sections in the Creasing styles. |

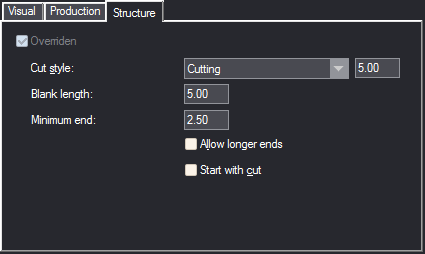

The Structure tab: Perforating styles

| Overridden | Select the check box to set a style structure different from that of the parent one. |

|---|---|

| Cut style | In the dropdown list, sets the style of the cut and, in the value box, the segment length. |

| Blank length | Sets the length of the empty space between the segments. |

| Minimum end | Sets the shortest length that the endmost segments can have. |

| Allow longer ends | Corrects incomplete endmost segments that result after the pattern has been calculated. Learn more about how to use the longer-ends correction. |

| Start with cut | Select the check box to make objects begin and end with segments in the style set in Cut style. |

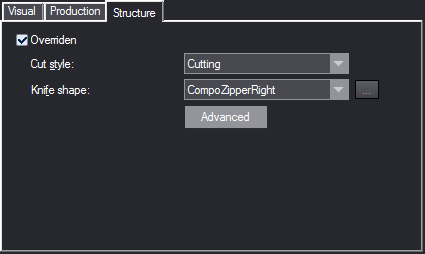

The Structure tab: Composite styles

| Overridden | Select the check box to set a style structure different from that of the parent one. |

|---|---|

| Cut style | In the dropdown list, select the

style to apply to the knife shape structure. NOTE: This is

the style that will appear in CAM and 3D drawings.

IMPORTANT: If you have opted for viewing composite styles, EngView applies the visual properties set for the style in Cut style. |

| Knife shape | In the dropdown list, select the

shape for the composite style.

TIP: To view the shape, click Advanced and inspect the table that appears. You can modify the properties of the shape — for example, length or angle). NOTE: You can design knife shapes different from the ones available in the dropdown list. To do so, see details about the structure of composite style profiles. Then load the new components into the EngView installation. By default, these components reside in \\ProgramData\EngView\Package Designer\SharedSettings\TEMPLATES\CompositeStyles\ |

| Advanced | Opens a dialog box in which you can view the component that defines the shape. You can edit the component using its parameters. |

- In the tabs, edit the settings as you want them to be.

- To complete the definition of styles, click OK.

Notes

- In the Global Styles dialog box, the Overridden check boxes are selected by default; they are unavailable for system styles that have no parent styles. An exception is a system style created from another system style — for example, the Stripping style has the Cutting style as parent.

- Since some of the system styles have additional properties — for example, CutCrease and Perforating and all custom styles based on them — the edit boxes displayed in the Global Styles dialog box may vary. In all cases, only the properties which are relevant to the selected style are displayed.

- You can drag styles up and down the list to position them where you need them to be.