By using an NC postprocessor you can either drive the NC machine directly through a COM port, or export the NC code to a file. You can customize the generated NC code for different type of NC controllers. The NC postprocessor contains a configuration file that provides HPGL output. All HPGL-compatible devices can then be driven through the generated file.

The procedure that explains how to generate the NC file and, in Step 2, how to send the file to the machine you work with.

To generate an NC file and send it to the machine

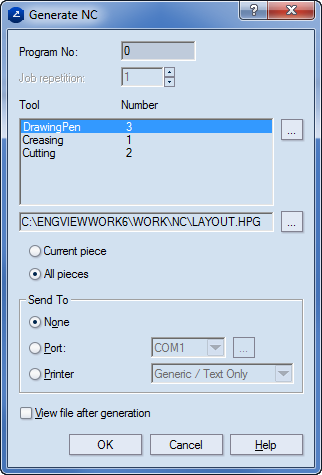

The NC Generation Properties dialog box appears.

Program No Shows the program number to be used on your machine.

Job repetition (Useful in multiple-job tasks) Sets the number of repetitions of the current job.

Tool Lists the tools in the current CAM template.

Number Displays the numbers of tools in the CAM template that correspond to the consecutive numbers of the tools on the actual machine. To change the number of a tool, select it, click the browse button  next to the table, and then, in the dialog box that appears, enter a tool number.

next to the table, and then, in the dialog box that appears, enter a tool number.

(NC file path) Displays where the generated NC file will be saved. To change the path, click the browse button  next to the field, and in the dialog box that appears select a location. NC files are stored as HPG files.

next to the field, and in the dialog box that appears select a location. NC files are stored as HPG files.

Current piece NC is generated only for the cutting of the currently selected piece.

All pieces NC is generated only for the cutting of all pieces — for example, if you have a design split in two, two NC files are generated that apply for the two parts of the split design.

Send Тo Determines how the NC commands are send to the machine you work with.

NOTE: If in a network several workstations are connected to the machine, the setting that follows must be configured for each of them. Consider your case:

and then select the port your machine works with.

and then select the port your machine works with.View file after generation If the check box is selected, the file containing the NC commands is displayed after you have clicked OK.