NOTES

- In the formula patterns, the arguments enclosed in square brackets — [...] — are optional: use them to extract data in formats that differ from the system defaults. IMPORTANT: When you are typing the formula and want to use the system defaults, you do not need to type the defaults — FALSE and TRUE. However, you need to refer to these defaults by leaving comma-separated blank spaces. For an example, see the default values in the examples below.

- StyleName The name of the style applied to the objects that are to be counted.

- ToolDirection The value of the angle that determines the object's direction relative to the x-axis — for example, 0, 45, 90.

- Tolerance The variation from the angle value set in ToolDirection in which the object will still qualify for counting.

USAGE NOTE: In the formula, type a value for the tolerance — for example, 1, 2, 0.5, 0.25 (see examples below). If you do not want to use a tolerance variation, type zero (0).

DEFAULT TOLERANCE NOTE: The EngView applies a standard, system-set tolerance — $epsa()$ (for angles, 0.001 degrees) and $epsd()$ (for distances, 0.0002 in the selected metrics).

NOTE ON ROTATED DESIGNS: If the design is rotated, the formulas require that the angle of rotation is entered — see the parameter ToolDirection in the formulas' syntaxes. In this case, the measurements are again made relative to the leftmost edge of the bounding rectangle, which, too, is rotated at the same angle as the design.

Applying the formula

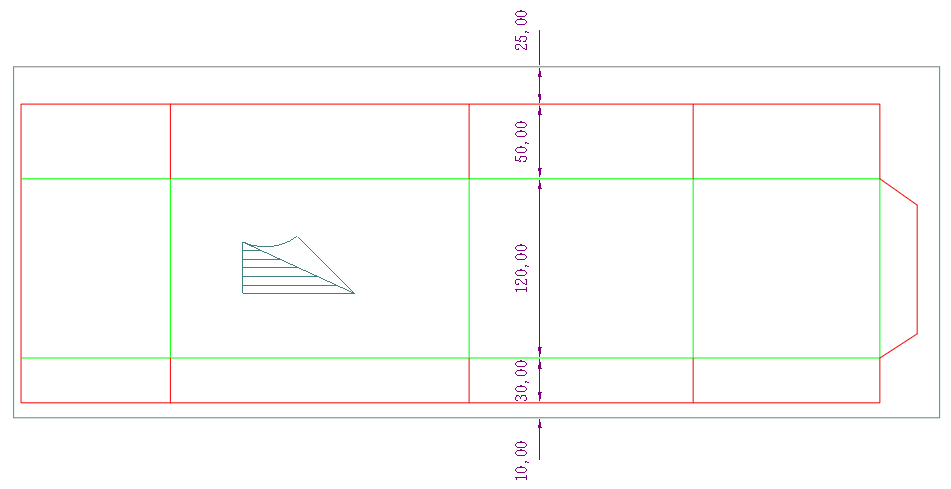

Examine the following 1up drawing, and then see the examples below. Note the indicated distances and see how EngView uses the formula to extract their values

Using the default values

| $OneUp1.ToolOffsetList(Creasing; false; true; 180-fd(); epsa(); mm ; n2 " – ")$ = 40 – 120 |

| $OneUp1.ToolOffsetList(Creasing; ; ; 180-fd(); epsa(); mm; n2 " – ")$ = 40 – 120 |

THE DISTANCES:

- The sheet's lower edge and the first crease line (40). Calculated by adding the distance between the sheet's edge and the lower cut line (10) and the distance between the cut line and the lower crease line (30).

- The lower and upper crease lines (120).

NOTE: The two formulas produce the same result, but the second uses spaces to refer to the default values.

Variant 1

| $OneUp1.ToolOffsetList(Creasing; false; false; 180-fd(); epsa(); ; n0 " – ")$ = 30 – 120 |

DISTANCES SHOWN:

- The lower cut line and the lower crease line (30).

- The lower and upper crease lines (120).

Variant 2

| $$OneUp1.ToolOffsetList(Creasing; true; true; 180-fd(); epsa(); ; n0 " – ")$ = 40 – 120 – 75 |

DISTANCES SHOWN:

- The sheet's lower edge and the first crease line (40). Calculated by adding the distance between the sheet's edge and the lower cut line (10) and the distance between the cut line and the lower crease line (30).

- The lower and upper crease lines (120).

- The upper crease line and the sheet's upper edge (75). Calculated by adding the distance between the upper crease line and the upper cut line (50) and that from the cut line and the sheet's upper edge (25).

Variant 3

| $OneUp1.ToolOffsetList(Creasing; true; false; 180-fd(); epsa(); ; n0 " – ")$ = 30 – 120 – 50 |

DISTANCES SHOWN:

- The lower cut line and the lower crease lines (30).

- The lower crease and upper crease lines (120).

- The upper crease line and the upper cut line (50).