Measuring tool positions оn inliner machines

Application

The formula produces a list of values that indicate the positions

— vertical or horizontal / against or along the flute direction —

of the creasing tools оn inliner machines. The values are the distances

of the creasing tools from one and the same reference object (sheet

edge or bounding rectangle).

The formulas count the lines according to:

- The angle at which the lines are positioned in the design.

- The style applied to them.

The formula

| To print |

In drawing |

Use |

| List of positions |

1up, layout |

$OneUpN.ToolPosList(StyleName, addLastCut, alignToSheet; ProductionDirection;

Tolerance; Units; Precision; L"separator")$ |

- THE PARAMETERS

- StyleName The name of the style applied to the objects

that are to be counted.

- addLastCut Takes into account the last cut. Values:

Yes, No. The default is No, which can be omitted.

- alignToSheet Yes/No (align to sheet) Defines whether

the distances to include the distance to the edge of the sheet.

Values: Yes, No. The default is Yes, which can be omitted.

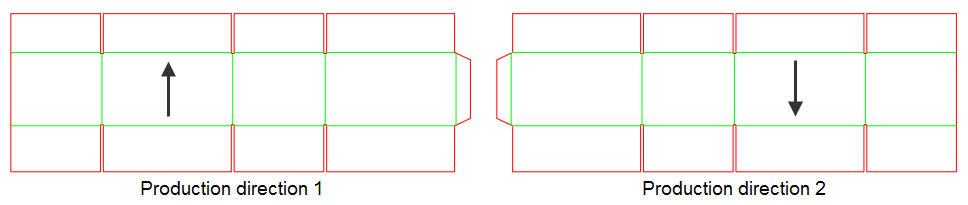

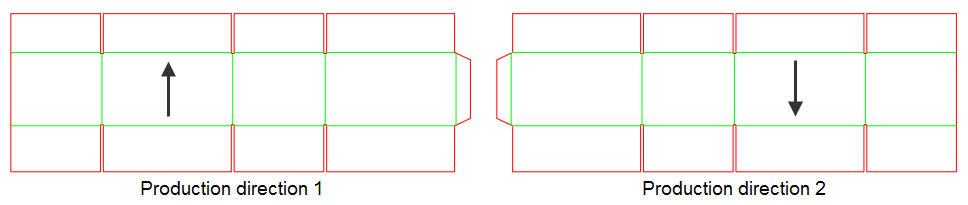

- ProductionDirection The value of the angle that

determines (1) horizontal or vertical /against or along flude

direction distances will be listed and (2) the production

direction of the design (see example below).

- Tolerance The variation from the angle value set

in ProductionDirection in which the object will

still qualify for counting. Type a value for the tolerance

— for example, 0.25. If you do not want to use a tolerance

variation, type zero (0).

- Units The measurement units in which EngView

will compute the result. To use the default

units, leave the argument empty.

- Precision How many symbols in the fractional part.

To use the default

units, leave the argument empty.

- L"separator" The symbol that will be printed

between the extracted distances. If you leave the argument

empty, the default

list separator is applied.

- Know your list separator: When typing a formula, make sure you separate

its elements with your computer's list

separator symbol. Yours may be different from the one used in this

guide. Examples (in red):

| With Semicolon |

With Comma |

| $Layout1.Length(Cutting; m; yes);

n2$ |

$Layout1.Length(Cutting, m, yes),

n2$ |

Applying the formula

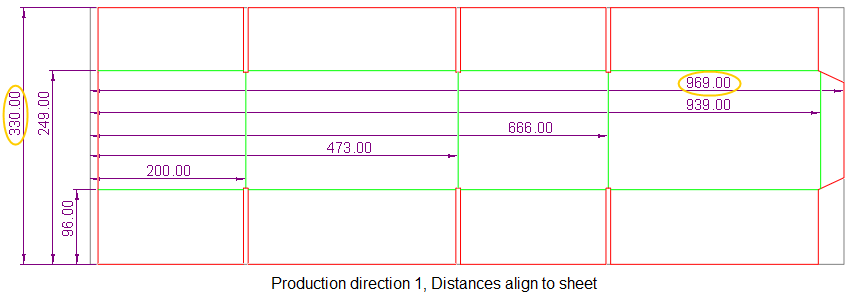

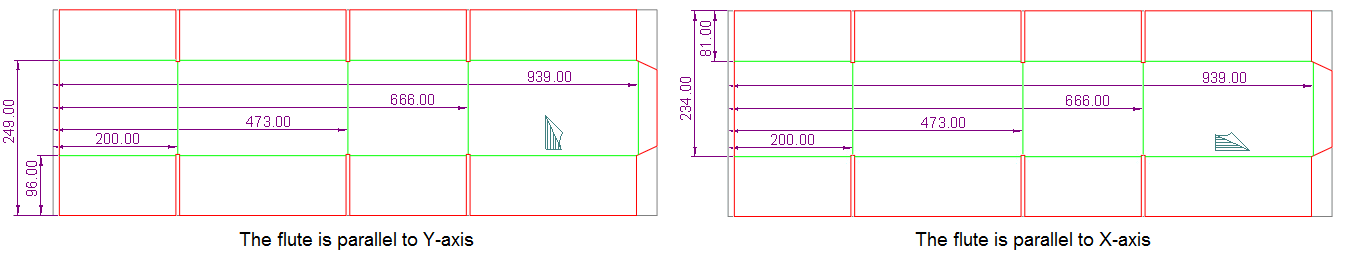

Examine the following 1up drawing, and then see the examples below.

Note the indicated distances and see how EngView uses the

formula to extract their values

1. Formulas extracting horizontal and vertical distances

| Distance Type |

Production Direction |

Physical Direction |

Value for ProductionDirection |

| Horizontal |

1 |

Left to right |

90 |

| Vertical |

1 |

Bottom to top |

180 |

| Horizontal |

2 |

Right to left |

270 |

| Vertical |

2 |

Top to bottom |

0 |

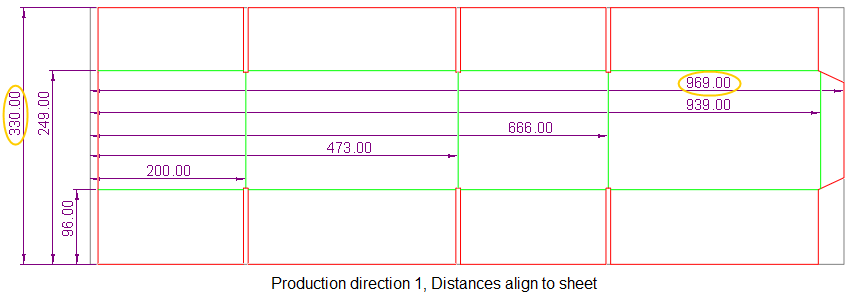

2. Extracting distances aligned to a sheet for production

direction 1

| Distance Type |

Direction |

Last Cut |

Use |

Result |

| Horizontal |

Left to right |

No |

$OneUp1.ToolPosList("Wheel Creasing", no,

yes, 90, 0, mm, n2)$ |

200.00,473.00,666.00,939.00 |

| Yes |

$OneUp1.ToolPosList("Wheel Creasing", yes,

yes, 90, 0, mm, n2)$ |

200.00,473.00,666.00,939.00, 969.00 |

| Vertical |

Top to bottom |

No |

$OneUp1.ToolPosList("Wheel Creasing", no,

yes, 180, 0, mm, n2)$ |

96.00,249.00 |

| Yes |

$OneUp1.ToolPosList("Wheel Creasing", yes,

yes, 180, 0, mm, n2)$ |

96.00,249.00, 330.00 |

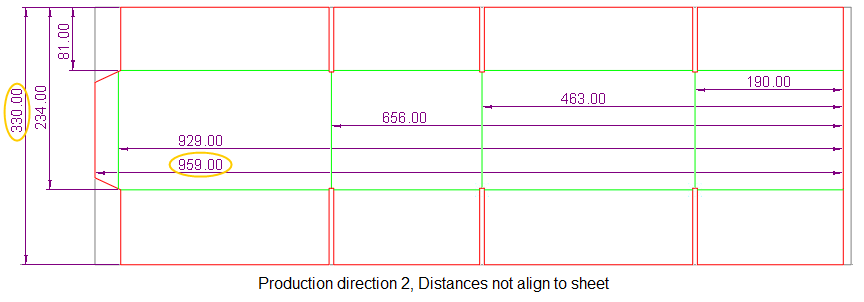

3. Extract distances not aligned to sheet for production

direction 1

| Distance Type |

Direction |

Last Cut |

Use |

Result |

| Horizontal |

Left to right |

No |

$OneUp1.ToolPosList("Wheel Creasing", no,

no, 90, 0, mm, n2)$ |

190.00, 463.00, 656.00, 929.00 |

| Yes |

$OneUp1.ToolPosList("Wheel Creasing", yes,

no, 90, 0, mm, n2)$ |

190.00, 463.00, 656.00, 929.00, 959.00 |

| Vertical |

Top to bottom |

No |

$OneUp1.ToolPosList("Wheel Creasing", no,

no, 180, 0, mm, n2)$ |

96.00,249.00 |

| Yes |

$OneUp1.ToolPosList("Wheel Creasing", yes,

no, 180, 0, mm, n2)$ |

96.00,249.00, 330.00 |

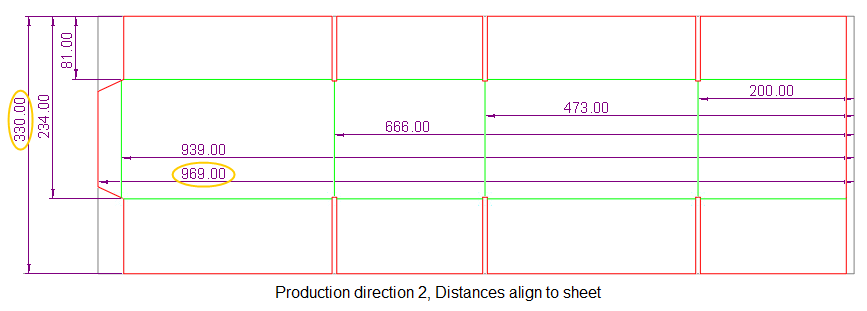

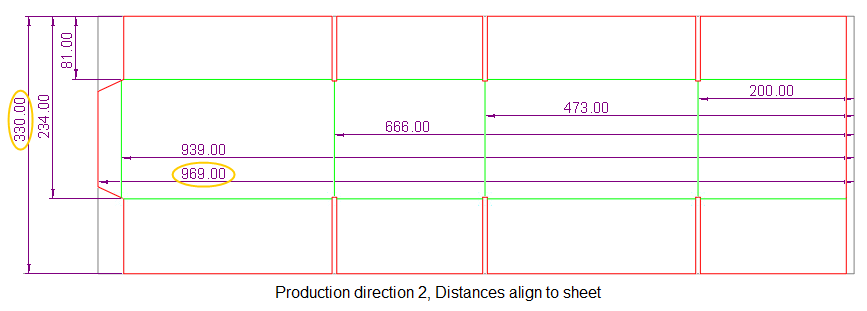

4. Extract distances aligned to sheet for production

direction 2

| Distance Type |

Direction |

Last Cut |

Use |

Result |

| Horizontal |

Right to left |

No |

$OneUp1.ToolPosList("Wheel Creasing", no,

yes, 270, 0, mm, n2) |

200.00,473.00,666.00,939.00 |

| Yes |

$OneUp1.ToolPosList("Wheel Creasing", yes,

yes, 270, 0, mm, n2)$ |

200.00,473.00,666.00,939.00,969.00 |

| Vertical |

Bottom to top |

No |

$OneUp1.ToolPosList("Wheel Creasing", no,

yes, 0, 0, mm, n2)$ |

81.00,234.00 |

| Top to bottom |

Yes |

$OneUp1.ToolPosList("Wheel Creasing",

yes, yes, 0, 0, mm, n2)$ |

81.00,234.00,330.00 |

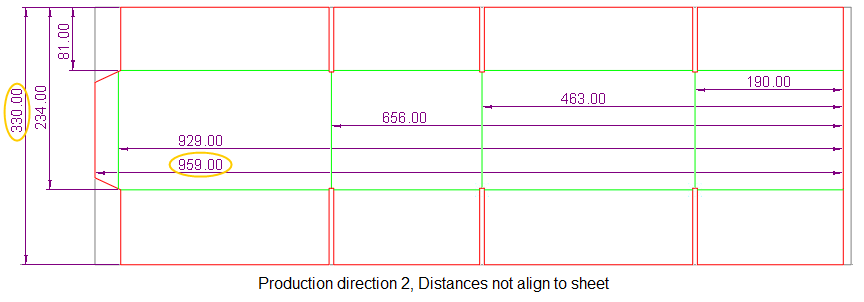

5. Extracting distances not aligned to sheet for production

direction 2

| Distance Type |

Direction |

Last Cut |

Use |

Result |

| Horizontal |

Right to left |

No |

$OneUp1.ToolPosList("Wheel Creasing", no,

no, 270, 0, mm, n2)$ |

190.00,463.00,656.00,929.00 |

| Yes |

$OneUp1.ToolPosList("Wheel Creasing", yes,

no, 270, 0, mm, n2)$ |

190.00,463.00,656.00,929.00,959.00 |

| Vertical |

Bottom to top |

No |

$OneUp1.ToolPosList("Wheel Creasing", no,

no, 0, 0, mm, n2)$ |

81.00,234.00 |

| Yes |

$OneUp1.ToolPosList("Wheel Creasing", yes,

no, 0, 0, mm, n2)$ |

81.00,234.00,330.00 |

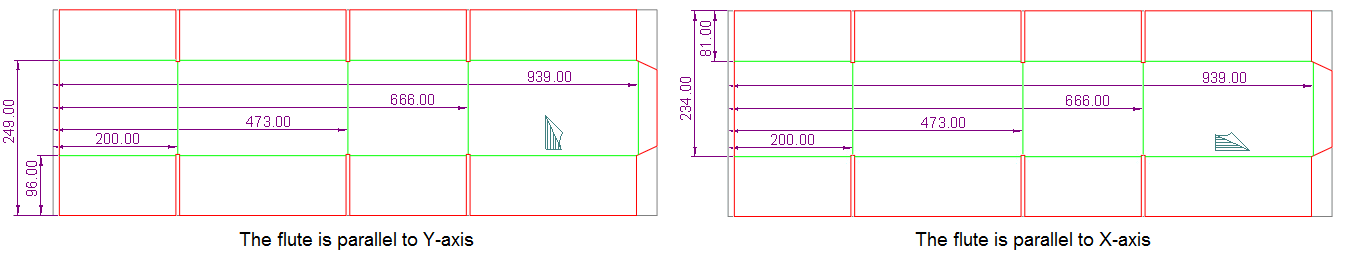

6. Formulas extracting distances by taking into account the flute

direction

When you need to extract distances against or along the flute direction,

use the fd() function as argument for ProductionDirection. It returns

the direction of the flute.

In the example that follows, identical formulas return different

results because they take into account the direction of the flute.

| Flute Direction |

Last Cut |

Sheet Edge |

Use |

Flute along y-axis |

Flute along x-axis |

| Against |

No |

Yes |

$OneUp1.ToolPosList("Wheel Creasing", no, yes, fd(), 0, mm, n2)$ |

200.00, 473.00, 666.00, 939.00 |

81.00,234.00 |

| Along |

No |

Yes |

$OneUp1.ToolPosList("Wheel Creasing", no, yes, fd()+90, 0, mm, n2)$ |

96.00,249.00 |

200.00,473.00,666.00,939.00 |