. In the Apply Layout Template to New Sheet dialog box that appears, click Opt. Sheet.

. In the Apply Layout Template to New Sheet dialog box that appears, click Opt. Sheet.Sheet optimization consists in a cost-benefit analysis of each sheet format you choose for a layout as well as the number of pieces you want to produce. It shows you the number of sheets you will need, the layout 1ups per sheet, the total number of layout 1ups that will be produced, the sheet's waste area, and the percentage of waste area for each sheet format. By optimizing the sheet you choose the optimal sheet format for your layout, that is, a sheet format that will have minimum waste sheet area for selected number of pieces.

Sheet optimization takes place in Automatic layout: Sheet Placement step.

To do sheet optimization

. In the Apply Layout Template to New Sheet dialog box that appears, click Opt. Sheet.

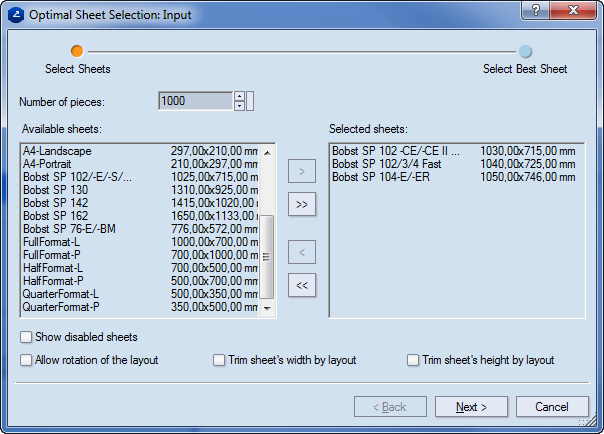

. In the Apply Layout Template to New Sheet dialog box that appears, click Opt. Sheet.The Optimal Sheet Selection: Input dialog box appears.

NOTE: The arrows alter the number by a default step of 1. To change it, click the small rectangle next to the arrows, and in the dialog box that appears, type a new step.

NOTE: To select multiple sheets, use SHIFT for consecutive sheets or CTRL for nonconsecutive ones. To remove sheets from the Selected sheets list, select them, and then click the left-pointing single-chevron button . To remove all the sheets in the Selected sheets list, click the left-pointing double-chevron button

.

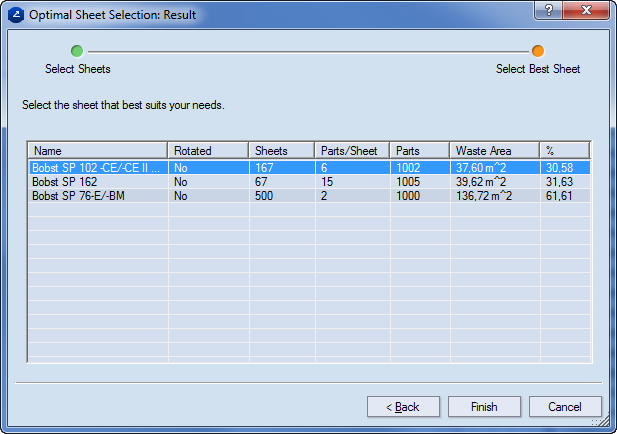

The Optimal Sheet Selection: Result dialog box appears.

Name The name of the sheet format as it appears in the sheet database.

Rotated Indicates — by Yes or No — if the layout array has been rotated.

Sheets The number of sheets needed for production of the selected number of pieces.

Parts/sheet The number of parts that can fit in each sheet of the sheet format.

Parts The number of parts that will be produced; usually it equals that of the selected number of pieces. However, sometimes the combination of the number of parts per sheet and the number of sheets needed for production results in a greater number of parts.

Waste area The waste sheet area as determined by the selected number of pieces and the sheet format.

% The waste area of the sheet if the selected number of pieces are produced using the sheet format.

IMPORTANT: The sheet optimization depends on whether in Automatic layout: Sheet Placement step you have selected Fit to sheet or Fill by counts options. Consider the following situations:

NOTE: See a visual step-by-step scenario of how to do sheet optmiziation.