Creating layout from multipart structures on a sheet material

You can produce a series of the same multipart structures — for

examples, a display or a piece of furniture — directly after you have

decided on its structure and design in 3D. You need only create layouts

of its components, send them to a production machine (a cutter, a

digital machine), and then assemble the cut components into actual

structures.

The nesting job procedure that follows takes you through the steps

of how to can create a layout by nesting

the parts of a structure on a sheet material. The example model

is ICB10001 Multiple-Shelf Display. The procedure starts from the

structure's assembled-state drawing.

The nesting job

- In the 3D model view, go to the assembled-state drawing.

- On the 3D tab toolbar, click Create Layout From 3D

.

.

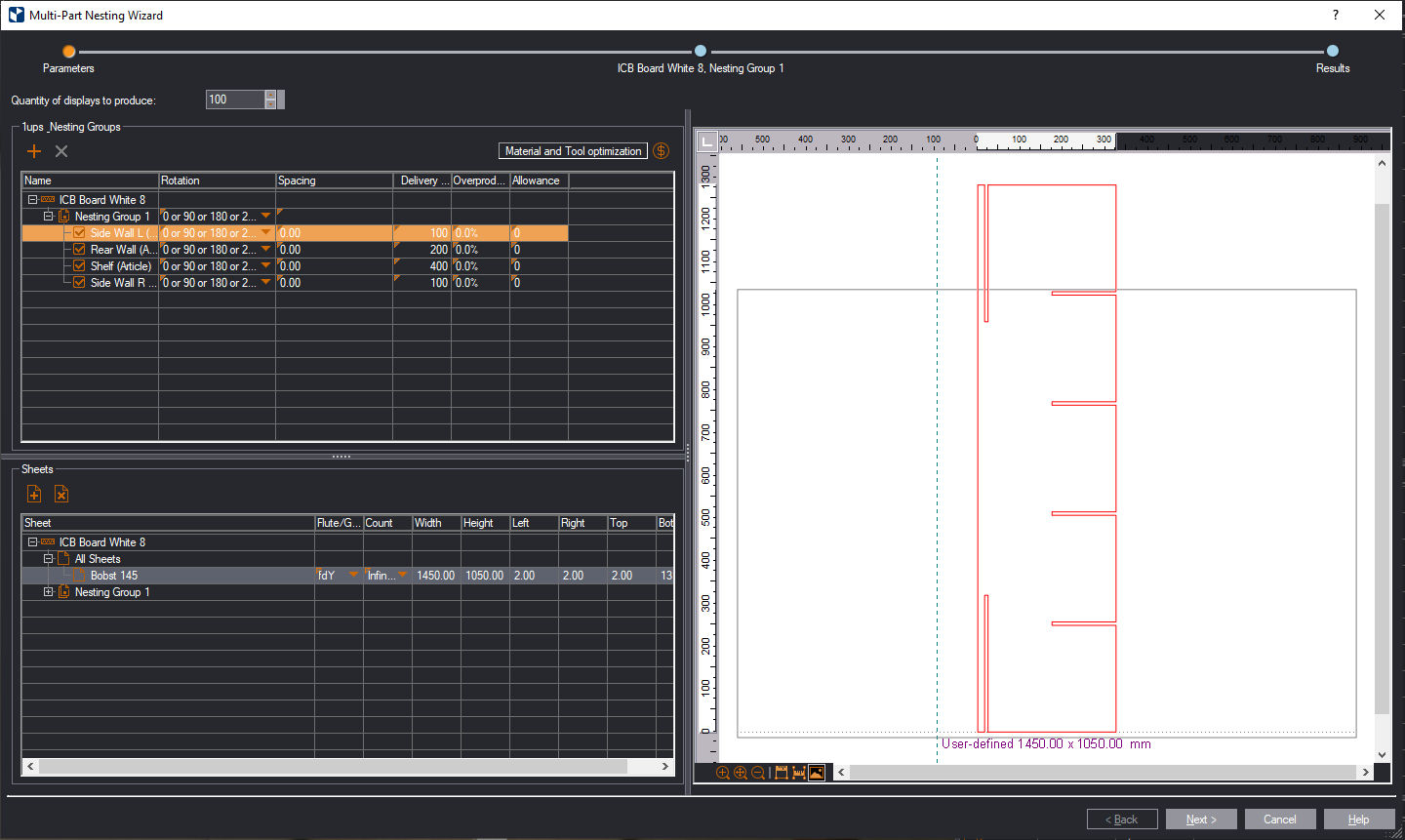

The Multi-Part Nesting Wizard opens at the

Parameters step. Scroll past the picture to learn how to read it.

| The progress bar |

The progress bar follows the sequence of steps that makes up

the nesting job. The first and last steps — Parameters and Results

— are permanent, while the number of the intermediate steps depends

on (1) the number of the materials used in the 3D model and (2)

the grouping of the parts for the actual nesting (see below).

The name of an intermediate step is a compound generated automatically

from the name of the used material and that of the nesting group.

In the example above, ICB Board White 16, Nesting Group 1. Scroll

below in the table to learn how to use nesting groups. |

| |

| Quantity of displays to produce |

Type how many finished products you want produced as a result

of the nesting job. |

| |

| 1up Nesting Groups |

Here you tell EngView

how to nest the parts on the sheet. When you select a part, it

appears in the preview area on the right. If you have defined

nesting groups in the materials

store, based on a particular material, these are loaded automatically.

IMPORTANT: If you make changes to the nesting

groups that you want to use in the future, you can update them

in the materials

store. Updating the store is automatic for rolled materials,

but not for sheet materials. So do it manually.

Learn how to define a nesting group. |

| Cost Parameters |

Opens a dialog box in which

you tell EngView how to calculate an estimate for the cost of

the production. This estimates does not offer an actual production

cost but is a instrument for ranking layout variants by lowest

cost. |

| Name |

The column displays three nesting job components:

- The name of the used material. Material names are added

automatically by EngView.

This name takes part in the EngView-generated

name of the nesting job's intermediate steps. You cannot edit

the name here.

- The nesting groups defined for the job. Each material used

in the 3D model defines its own set of nesting groups. There

is always a default group, Nesting Group 1, whose name you

can neither modify nor delete. You can tell EngView to always

nest certain parts together. In this case, you need to group

the parts into a separate group. To create a group:

- Select the name of the material.

- Click the Plus button above.

- In the row that appears, edit the group's name as you

need it.

- From Nesting Group 1, drag into the new group the parts

that you want to group individually into the new group.

- Repeat Steps 1–4 for each new group you choose to create.

- The indvidual parts that will take part in the nesting

job. By default, when you begin, you see all available parts

in Nesting Group 1. If you choose to have some parts always

processed together, create nesting groups for them. If you

do not want to use a part in the nesting job, leave its check

box empty. Article indicates the name of the article

applied onto the part.

|

| Rotation |

Type an angle that EngView

will use to rotate the part while populating the sheet. To specify

a value for all the parts, set it across the name of the nesting

group. To set an individual angle value for a part, type it across

the part's name. |

| Spacing |

Type a gap between the parts. To specify a global value, type

it across the name of the nesting group. To set an individual

spacing for a part, type it across its name. |

| Delivery Quantity |

Specify how many pieces of this part you want produced. |

| Overproduction |

Specify as percentage the amount of production that the customer

is willing to pay for in excess of the combined total as

calculated from Quantity + Allowance. |

| Allowance |

Set spoilage for the current part. Spoilage is the number of

excess pieces that will be produced for the purpose of setting

up the die. Generally, after setting up the die, these pieces

are recycled. |

| |

| Sheets |

The sheets that will be used in the nesting job. Each material

used in the 3D model defines its own set of sheets. NOTE: To add

a sheet, click any row in the table, and then click the Plus button;

then, from the list that appears, select a sheet. To delete a

sheet, click it, and then click the Remove button. |

| The Sheets List |

A list of the sheets selected for production. For each material,

you see two default sheets groups: All Sheets and Nesting Group

1. For each new nesting group you choose to create, a new sheets

group appears here. If you are working with multiple nesting groups,

here you can add sheets to each one of them. To add a sheet:

- Select a group's name.

- Click the Plus button.

- From the list that appears, select the sheet that you

want to work with.

- Repeat Steps 1–3 for each sheet you want to add. Notice

that each sheet you add automatically goes into both its

own nesting group and the All Sheets group.

NOTE: In a nesting group, you can add multiple sheets but use

only some of them. To choose which ones to use, use the mouse

to select or deselect the check box in front of each sheet. Alternatively,

use the Space bar to select or deselect sheets and nesting groups. |

| Flute/Grain direction |

Sets whether the sheet will take into account the grain or

flute of the material. The options are:

- fdX. Arranges the parts according to the horizontal

flute/grain.

- fdY. Arranges the parts according to the horizontal

flute/grain.

- fdAny. Ignores the direction of the flute/grain.

|

| Count |

Sets the number of sheets available, the default value is Infinite.

You can set your own number. In that case, if EngView

computes a number that is greater than the one set here, a red

notification and a tooltip alert will appear in the Total Sheet

Count column in the Results step. |

| Width |

The horizontal length of

the sheet. |

| Height |

The vertical length of the

sheet. |

| Left, Right, Top, Bottom |

The values for the sheet's left, right, upper and lower margins |

| |

| The Preview Pane |

A preview of the part selected in the Name column |

Single Object Dimension Single Object Dimension |

Click to measure the lengths

of individual objects in the preview area. |

Associative (Two Object) Dimension Associative (Two Object) Dimension |

Click to measure distances

between two objects. |

Show Images Show Images |

If images have been applied to the parts, clicking this button

hides/displays them. |

Clipped Image Clipped Image |

If images have been applied onto the parts that go outside

the parts, clicking this button clips the images to make them

fit the parts' actual areas. |

View Bleed View Bleed |

Hides/Displays the bleed in the preview area. |

- Click the Cost Parameters icon

and in it

set how you want EngView

to compute the cost estimate. See details

about how to do this.

and in it

set how you want EngView

to compute the cost estimate. See details

about how to do this.

- Edit the sheet and grouping settings to make them work for

your case. Then click Next to continue.

An intermediate step appears. A general info

about the intermediate steps follows:

The number of intermediate steps is determined by (1) the number

of used materials and (2) the number of nesting groups (see the note

for progress bar in the previous step). The name of an intermediate

step is a compound from the name of the used material and that of

the nesting group. This means that if you work with multiple materials,

you will have as many individual pages as materials, and if you work

with multiple nesting groups, you will have as many pages as groups.

In other words, if you work with:

- One material and one nesting group, the wizard will display

one intermediate step.

- Two materials and two nesting groups, the wizard will display

four intermediate steps.

Scroll past the picture that follows to learn how to read an intermediate

step.

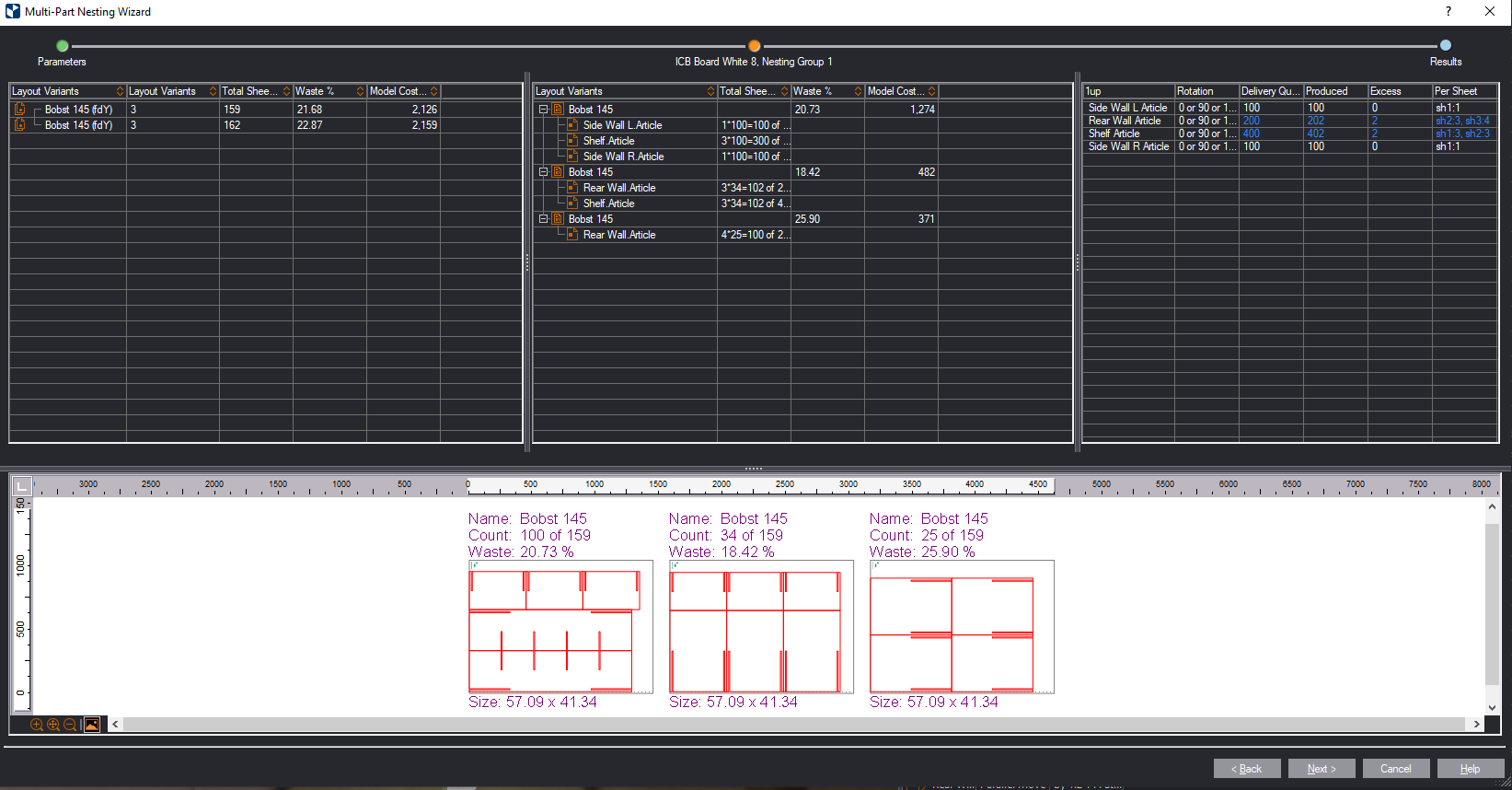

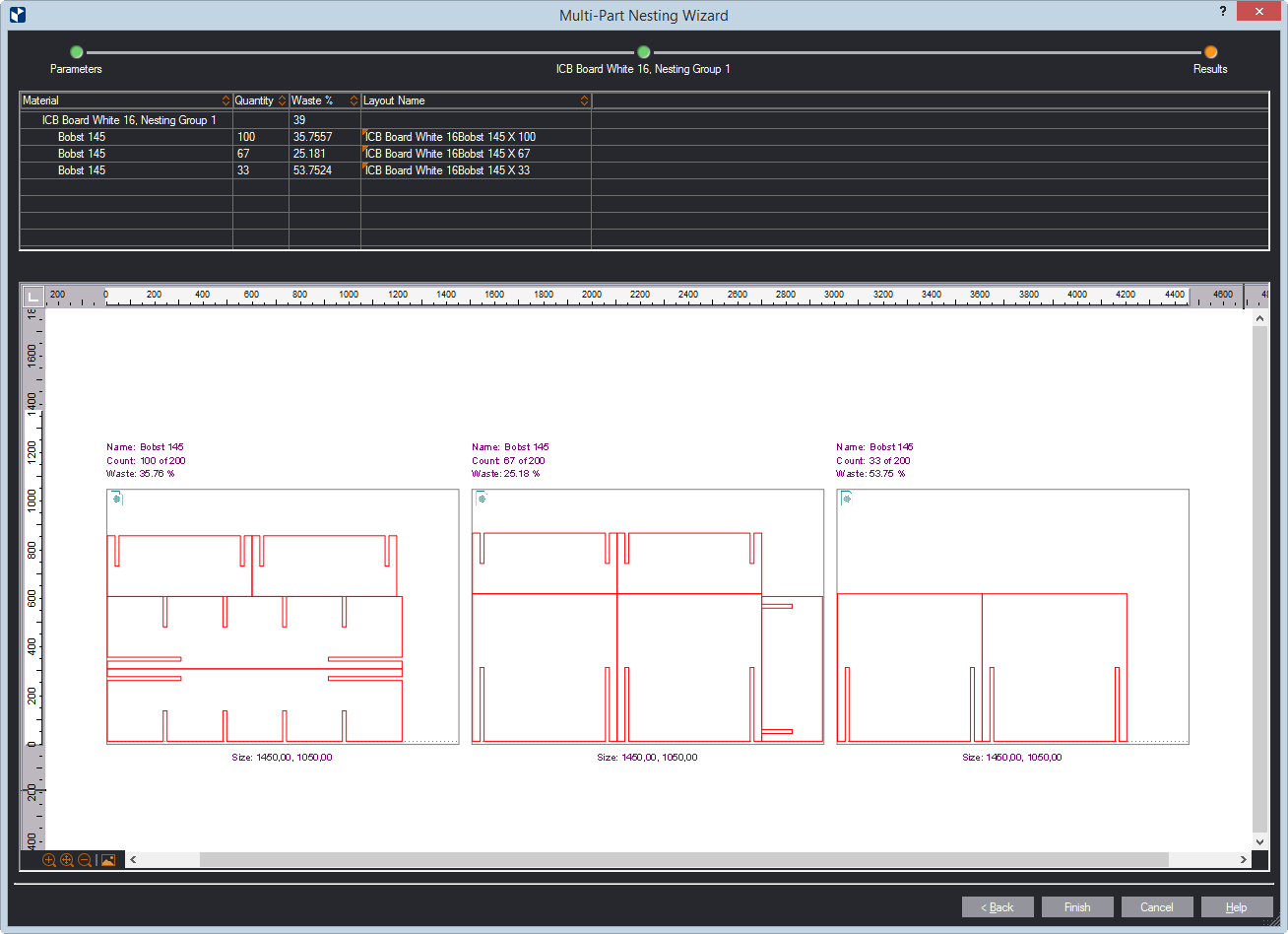

| The Left-Hand Pane |

The pane lists the layout variants that EngView

has computed from the parameters you have supplied. The variants

are listed in descending order, ranked by the lowest cost and

waste. |

| Layout Variants |

The names of the sheets that EngView

will use for the nesting job. |

| Layout Variants |

How many dies (or sheets) the job requires. |

| Total Sheet Count |

The total number of sheets EngView

has computed for the nesting job. Note that if you see a red text

and an alert tooltip here, this means that in Count (in

the Parameters step) you have entered a number that is smaller

than the one EngView

has computed. This alert will not stop the nesting job, but it

is best to go back to the Parameters step and modify the value

in Count. |

| Waste % |

The overall waste in relation to the total area of the sheet |

| Model Cost Estimate |

The relative cost for the variant |

| |

| |

| The Middle Pane |

The pane lists a breakdown of the parts combinations by particular

sheet. For each part are displayed its production volume (in Delivery

Qnty, Produced and Excess), spatial positioning on the sheet (Rotation),

and per-sheet distribution. |

| The Right-Hand Pane |

The pane lists the 1ups (parts) featured in the variant selected

in the left-hand pane. For each part are displayed its production

volume (in Delivery Qnty, Produced and Excess), spatial positioning

on the sheet (Rotation), and per-sheet distribution. |

| 1up |

The name of the 1up (part). When you select a part, it is highlighted

in the preview pane in all the sheets it appears. |

| Rotation |

The angle of rotation for the part when arrayed in the sheet |

| Delivery Quantity |

How many pieces of this part you want produced. If colored

results appear, see what they mean*. |

| Produced |

The number of parts the nesting job will actually produce.

If colored results appear, see what they mean*. |

| Excess |

The difference between the values in Produced and in

Delivery Quantity. If colored results appear, see what

they mean*. |

| Per Sheet |

Indicates how many pieces of the part there are in each sheet

in which the part appears. Examples:

- sh1:1 means Sheet 1 contains one pieces of the part.

- sh2:3 means Sheet 2 contains three pieces.

- sh2:2, sh3:6 means Sheet 2 contains two pieces and Sheet

3 contains six pieces.

When you select the row, EngView

highlights the part in the preview pane in all the sheets it appears.

If colored results appear, see what they mean*. |

| |

| *Colored results |

Depending on the amounts you have set for a nesting job, in

the right-hand pane you may see colored results in the columns

Delivery Quantity, Produced, Excess and Per Sheet. The colors

means as follows:

- Blue. The amounts

produced are greater than what you have set. That means you

will have surplus output.

- Red. The amounts produced

are smaller than what you have set. This means you will have

smaller output than what you need.

|

| |

| The Preview Pane |

A preview of the layouts EngView

has computed under the selected variant. If a row is selected

in the right-hand pane, the respective part is highlighted in

all the sheets in which it appears. |

Single Object Dimension Single Object Dimension |

Click to measure the lengths

of individual objects in the preview area. |

Associative (Two Object) Dimension Associative (Two Object) Dimension |

Click to measure distances

between two objects. |

Show Images Show Images |

If images have been applied to the parts, clicking this button

hides/displays them. |

Clipped Image Clipped Image |

If images have been applied onto the parts that go outside

the parts, clicking this button clips the images to make them

fit the parts' actual areas. |

View Bleed View Bleed |

Hides/Displays the bleed in the preview area. |

.

.

Single Object Dimension

Single Object Dimension Associative (Two Object) Dimension

Associative (Two Object) Dimension Show Images

Show Images Clipped Image

Clipped Image View Bleed

View Bleed and in it

set how you want EngView

to compute the cost estimate. See

and in it

set how you want EngView

to compute the cost estimate. See